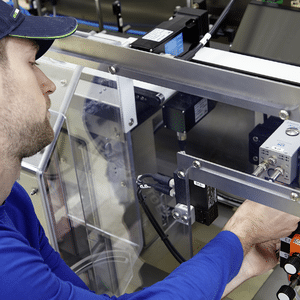

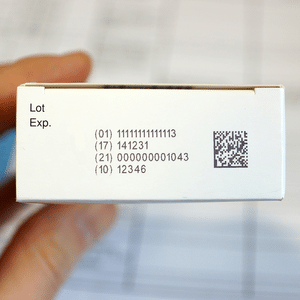

Perform semi-automatic aggregation of serialized packages to a case and optionally to a pallet. Verify product codes and label artwork for additional quality control measures using a High-Resolution Camera.

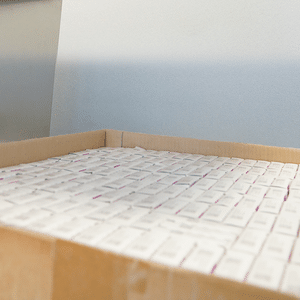

Supports Multi-Aggregation

Aggregates multiple items packaged in layers within a shipping case and verifies codes using an advanced software algorithm.

One Click Aggregation

An automatic focusing high-resolution camera captures serialized cartons and adds them to the aggregation hierarchy with just one click.

Easy Product Changeovers

The semi-automatic setup of cases up to 500 mm high for inspection and aggregation of a wide variety of packages allows for easy product changeovers.

Efficient Case Aggregation Plus Code/Label Verification

En savoir plus solutions de suivi et de traçabilité 🡢

| Solution de suivi et de traçabilité | Agrégation |

| Types de produits | Orienté Paquets Cas Palettes |

| Conception du système | manuel |

| Dispositifs de lecture | High Resolution Camera |

| Nombre de dispositifs de lecture | 1 |

| Débit | manuel |

| Logiciel compatible | PLM Direct Agrégation PLM |

| Dimensions (H x L x P) | 2400 x 1057 x 1029 mm |

| IHM | 15″ 15″” |

| Case Length | max. 600 mm |

| Case Height | max. 500 mm |

| Case Width | Max. 400 mm |

Verifies label information of multiple cartons simultaneously using a powerful High-Resolution Camera. Records and validates a wide variety of codes.

Read fine detailed datamatrix or QR codes down to 0.3 mm module per code. Ideal for applications, such as small labels or those requiring advanced codes.

The standard footprint of the T16 design is 1057 mm wide, allowing the system to fit even in small production environments.

PCE Line Manager (PLM) can easily be configured for multiple aggregation scenarios, supporting updates as business needs change.

Utilisez le logiciel PCE Line Manager (PLM) pour un contrôle complet des processus de production en vue de la sérialisation et de l'agrégation. Choisissez PCE Site Manager (PSM) pour l'intégration de l'entreprise avec l'infrastructure informatique du site.

Un réseau mondial d'experts en services fournit une assistance rapide à distance et sur site. Notre offre de services complète vous permet d'atteindre la conformité réglementaire, des performances élevées et une disponibilité maximale tout au long du cycle de vie de votre équipement d'inspection de produits.