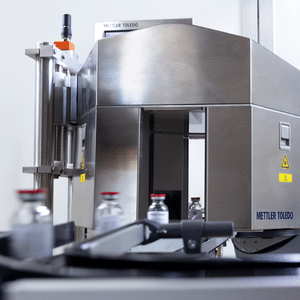

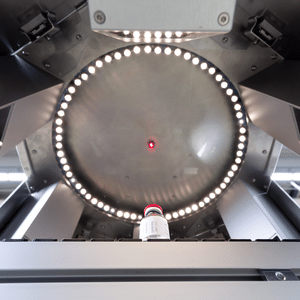

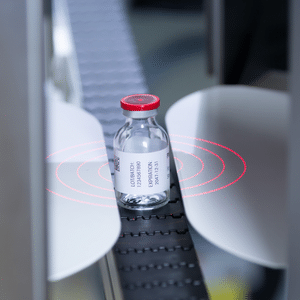

Serialization using 6 image sensors to capture a 360° view of any round container such as bottles or vials. The compact design is optimized to fit over existing conveyors for minimal disruption to production lines.

Serialization for any Round Container

Serialize labels on bottles, vials and cans through a full 360° view of packaging with minimal disruption to existing production efficiencies.

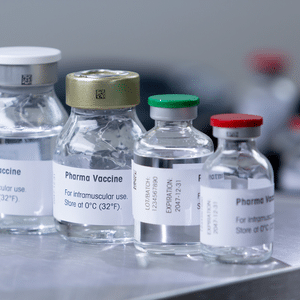

Supports a Range of Round Package Sizes

Accommodates round packages such as bottles, cans, or vials sized from 10 mm to 110 mm using either a fixed focal lens or liquid lens.

Reads Small Sized Serialization Codes

Choose from our fixed focal lens or liquid lens 360° Inspection Head to read modules as small as 0.2 mm per code.

| Solution de suivi et de traçabilité | Sérialisation |

| Types de produits | Bottles Vials Round |

| Conception du système | intégré |

| Dispositifs de lecture | Luminescence Sensor Smart Camera 360 Scanning Head Laser Scanner Smart Camera |

| Nombre de dispositifs de lecture | up to 4 |

| Débit | jusqu'à 300 ppm |

| Logiciel compatible | Sérialisation PLM |

| Dimensions (H x L x P) | 394 x 589 x 510 mm |

| Hauteur du produit | max. 230 mm |

| Largeur du produit | 6 – 110 mm diameter |

| IHM | 15″ 15″” |

Choose from multiple PCE software options to manage production devices (printer, 360 inspection head, extra cameras and rejectors) and connect to current ERP, MES or cloud environments.

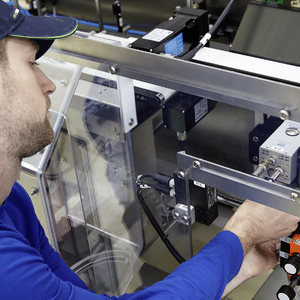

Choose the electrical enclosure, cabinet and HMI needed for your application. Fit the 360° Inspection Head over existing lines, or use a standalone frame to accommodate any space requirements.

Use an additional smart camera to read inkjet printed information such as serialized helper codes, or expiration dates on caps or lids. Can detect both black printed and UV ink.

Helps you meet global regulatory standards, such as GMP (Good Manufacturing Practices), US FDA 21 CFR Part 11 practices or others unique to your region.

The IP65-rated stainless steel enclosure helps minimize ambient light interference, allowing for effective code reading on a variety of print surfaces (labels, plastic, metals) using the 6 image sensors.

Supports the inspection of already serialized labels for compliance of existing processes, adding an extra step to help ensure labels meet your quality standards.

Un réseau mondial d'experts en services fournit une assistance rapide à distance et sur site. Notre offre de services complète vous permet d'atteindre la conformité réglementaire, des performances élevées et une disponibilité maximale tout au long du cycle de vie de votre équipement d'inspection de produits.