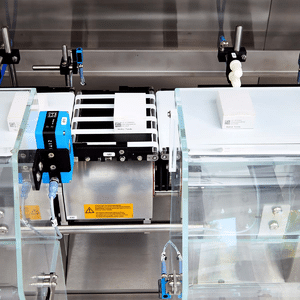

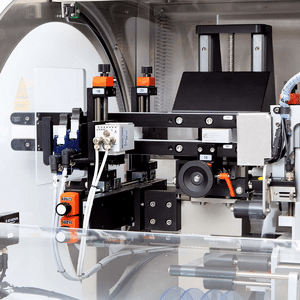

Integrates three applications into one compact serialization system. Printing, visual code verification, and secure tamper-evident sealing for compliance in global traceability.

Advanced 3-in-1 Package Processing

The system provides serialization, mark and verification, and tamper-evident sealing to help ensure compliance for EU FMD 15415.

Compliance for Tamper Evidence

The system applies tamper-evident seals to cartons after serialization in accordance with the EU delegated act 2011/62.

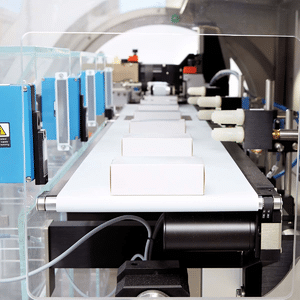

Fully Automated Serialization

Supporting throughputs of up to 300 ppm for automated item-by-item serialization that includes tracking, printing, and verification.

| Solution de suivi et de traçabilité | Sérialisation |

| Types de produits | Cartons Orienté |

| Conception du système | automatisé |

| Dispositifs de lecture | Caméra intelligente |

| Nombre de dispositifs de lecture | up to 3 |

| Débit | jusqu'à 300 ppm |

| Logiciel compatible | PLM Direct Sérialisation PLM |

| Dimensions (H x L x P) | 2297 x 1449 x 1681 mm |

| Hauteur du produit | 20 – 100 mm |

| Largeur du produit | 65 – 200 mm |

| Longueur du produit | 25 - 200 mm |

| IHM | 15″ 15″” |

This highly flexible system is suitable for a large variety of product types and sizes up to 200mm width. Additionally, the XMV-TE provides easy and quick product changeovers.

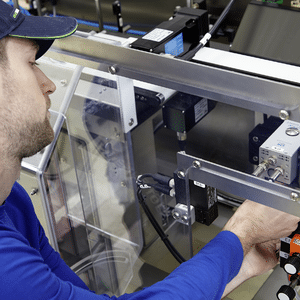

Increased compliance with a complete enclosure with electronic locks preventing access during production providing additional operator safety. The transparent enclosure allows full visibility of the production run.

L'analyse en ligne de la qualité d'impression du code datamatrix pendant le processus de production, conformément à la norme ISO 15415, permet d'améliorer les performances de la ligne.

Turnkey solution saves valuable production space and ensures quick and simple integration into new or existing production lines. Inside deflectors and a bottom plate contribute to easy and fast production line clearing.

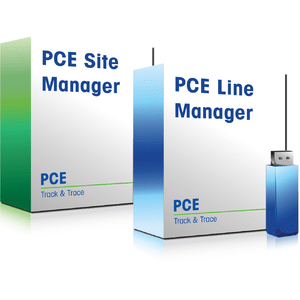

Use PCE Line Manager (PLM) software for complete line control of production processes for serialization. Choose PCE Site Manager (PSM) for enterprise integration with site-wide IT infrastructure.

Meets current regulatory requirements such as EU delegated act 2011/62 EU and related tamper-evident norm EN 16679. Easily upgrade the software to meet future compliance requirements as needed.

Un réseau mondial d'experts en services fournit une assistance rapide à distance et sur site. Notre offre de services complète vous permet d'atteindre la conformité réglementaire, des performances élevées et une disponibilité maximale tout au long du cycle de vie de votre équipement d'inspection de produits.