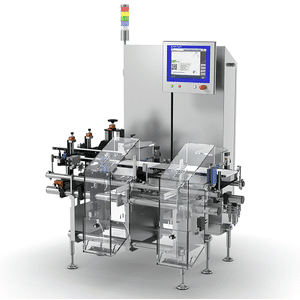

This powerful solution combines proven item serialization with high precision weighing using FlashCell™ EMFR technology and visual inspection of the product label and artwork. The compact design features a single HMI for intuitive operation.

Maximum Productivity

Minimal manual operator intervention due to automated product handling and sorting options for increased productivity.

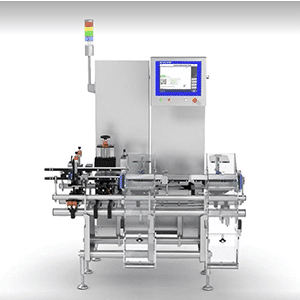

Exceptional Product Handling

The transversal adjustment and top-bottom-conveyor offer smooth product transfer and handling during the serialization and weighing process.

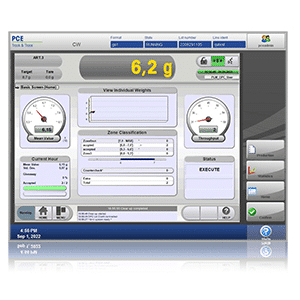

Software and Control Excellence

Full integration of the checkweighing and serialization software on a single HMI for intuitive system operation.

Powerful Serialization With High-precision Weighing and Visual Inspection

Explore more track and trace solutions

| Track & Trace Solution | Serialization Mark & Verify |

| Product Types | Cartons Oriented |

| System Design | automated |

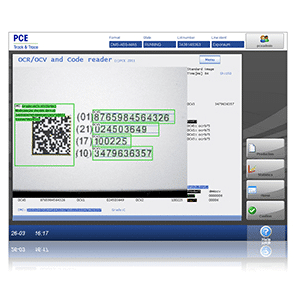

| Reading Devices | Smart Camera |

| Number of Reading Devices | up to 2 |

| Throughput | up to 300 ppm |

| Compatible Software | PLM Direct PLM Serialization |

| Dimensions (H x W x D) | 2067 x 1580 x 1360 mm |

| Product Height | 10 – 200 mm |

| Product Width | 45 – 200 mm |

| Product Length | 25 – 200 mm |

| HMI | 15″ 15″” |

| Accuracy | from ± 0.01 g (10 mg) |

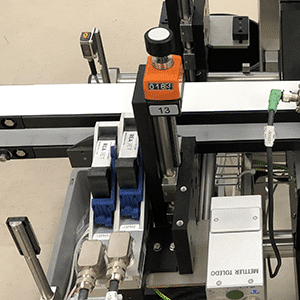

| Weighing Technology (Load Cell) | EMFR |

Based on the flexible C-Series design, it can be adapted to any production and application need. A wide range of options for mechanical, product handling, software and controls available in standard or customized additions to maximize process optimization.

The space-saving design is optimized to the carton size, desired throughput and maximum weight of the products. Integrating three inspections in one compact system maximizes production line space at only 1600 mm in length.

The open frame architecture provides easy access for cleaning and maintenance, as well as retrieving products that have fallen off the production line. Easy conveyor belt changes and removable catch bins support fast cleaning.

100% dynamic weight control supports compliance with weighing regulations by avoiding over-fill or carrying out completeness checks. The high performance EMFR load cell with FlashCell™ technology delivers exceptional accuracy at high throughputs.

The systems feature dedicated pharmaceutical process safety options and functionalities supporting FDA 21 CFR Part 11 and GMP compliance. As regulations change, simple software updates can be carried out to protect the hardware investment.

The PCE Line Manager (PLM) provides global control as the unified interface to help monitor and manage serialization. It can easily be configured for multiple serialization and visual inspection scenarios, supporting updates as business needs change.

A global network of service experts provide fast remote and on-site support. Our comprehensive service offer allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.