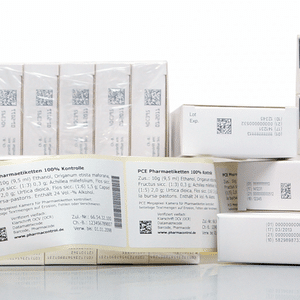

Serialize a wide range of oriented items, such as cartons, bundles, or labels using up to 4 smart cameras. Industry proven, modular and compact components facilitate easy integration into various production lines or packaging machines.

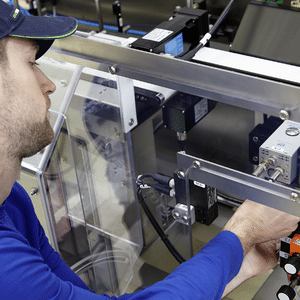

Easily Integrate Serialization

Integrate serialization into your production line. As packages pass through the system, codes are applied, verified, and serialized – in one solution.

Modular System Design

The T53 allows easy integration into existing or new production lines. The modular components provide flexibility to fulfill individual requirements.

Additional Quality Checks

Perform Quality Checks such as verifying codes of already serialized labels, to help ensure compliance and meet quality standards.

| Track & Trace Solution | Serialization |

| Product Types | Cartons Oriented Labels Bundles Cases Pallets |

| System Design | integrated |

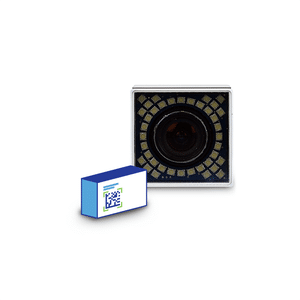

| Reading Devices | Luminescence Sensor Scanning Head Laser Scanner Smart Camera |

| Number of Reading Devices | up to 6 |

| Throughput | up to 300 ppm |

| Compatible Software | PLM Serialization |

| HMI | 15″ 15″” |

Compact enclosure on cameras and sensors helps to minimize exposure to dust and debris, providing consistent and reliable results with minimal downtime for maintenance.

Accommodates cartons, labels, or even rectangular bottles of varying shapes or sizes for serialization.

The component design is optimized for enivronments with limited space and can easily be installed with minimal disruption of the existing packaging line.

In-line analysis of the datamatrix code print quality during the production process according to ISO 15415 – supports advanced line performance.

Meets current regulatory requirements and is easily upgradeable for future requirements and regulations. As regulations change, simple and quick software updates help protect the hardware investment in the long-term.

Use PCE Line Manager (PLM) software for complete line control of production processes. Choose PCE Site Manager (PSM) for enterprise integration with site-wide IT infrastructure.

A global network of service experts provides fast remote and on-site support. Our comprehensive service offering allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.