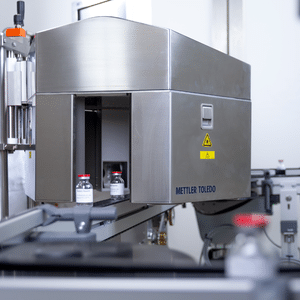

Marking and verifying print quality on round packages using 6 image sensors to capture a full 360° view. Three types of verification are available: Presence, Quality, and Reference Check. Existing printers can easily be integrated.

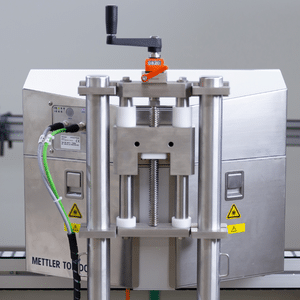

Flexible and Space Saving Integration

Install the 360 Inspection Head over conveyors, into new equipment or on a standalone frame with minimal space requirements. Add sensors as required.

Automated Quality Assurance

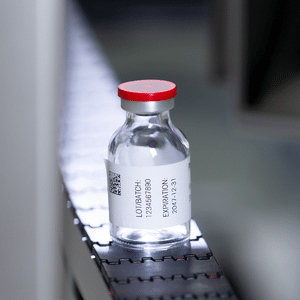

Offers inline quality assurance of product packaging by detecting print or labeling errors as early as possible in the production process.

Compact Enclosure Delivers Best Quality

The compact IP65-rated stainless steel enclosure minimizes ambient light exposure, allowing the 6 image sensors to perform optimal 360° verifications.

| Track & Trace Solution | Mark & Verify |

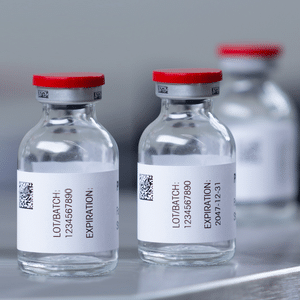

| Product Types | Bottles Vials Round |

| System Design | integrated |

| Reading Devices | Luminescence Sensor Smart Camera 360 Scanning Head Laser Scanner Smart Camera |

| Number of Reading Devices | up to 6 |

| Throughput | up to 500 ppm |

| Compatible Software | PLM Mark & Verify |

| Dimensions (H x W x D) | 394 x 589 x 510 mm |

| Product Height | max. 230 mm |

| Product Width | 6 – 110 mm diameter |

| HMI | 15″ 15″” |

The compact and modular design allows an easy installation of the Smart Camera 360 into existing or new production lines. Minimal downtime necessary when installing the hardware and software into existing production lines.

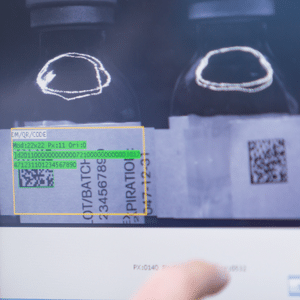

Presence Check verifies that a required attribute is present. Quality Check helps to ensure that an attribute has the required quality. Reference Check verifies that the attribute matches a given reference. All methods can be combined as needed.

The system supports multiple sensors such as smart cameras, barcode scanners, and machine readers and provides Presence, Quality, and Reference Checks. Existing printers can easily be integrated.

In-line analysis of the datamatrix code print quality during the production process according to ISO 15415 – supports advanced line performance.

Meets GMP requirements and is easily upgradeable for future requirements. As regulations change, simple and quick software updates help protect the hardware investment in the long-term. Mark & Verify systems can be upgraded to serialization systems.

A global network of service experts provides fast remote and on-site support. Our comprehensive service offering allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.