Integrates three applications into one compact serialization system. Printing, visual code verification, and secure tamper-evident sealing for compliance in global traceability.

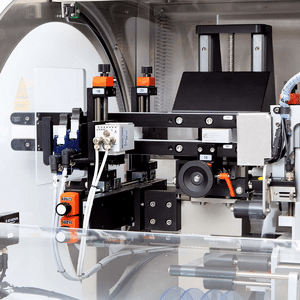

Advanced 3-in-1 Package Processing

The system provides serialization, mark and verification, and tamper-evident sealing to help ensure compliance for EU FMD 15415.

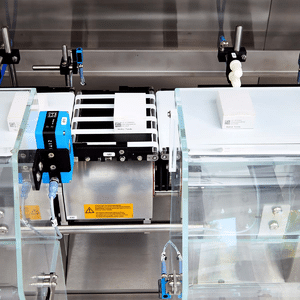

Compliance for Tamper Evidence

The system applies tamper-evident seals to cartons after serialization in accordance with the EU delegated act 2011/62.

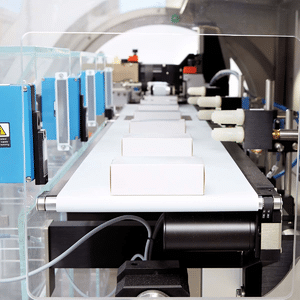

Fully Automated Serialization

Supporting throughputs of up to 300 ppm for automated item-by-item serialization that includes tracking, printing, and verification.

| Track & Trace Solution | Serialization |

| Product Types | Cartons Oriented |

| System Design | automated |

| Reading Devices | Smart Camera |

| Number of Reading Devices | up to 3 |

| Throughput | up to 300 ppm |

| Compatible Software | PLM Direct PLM Serialization |

| Dimensions (H x W x D) | 2297 x 1449 x 1681 mm |

| Product Height | 20 – 100 mm |

| Product Width | 65 – 200 mm |

| Product Length | 25 – 200 mm |

| HMI | 15″ 15″” |

This highly flexible system is suitable for a large variety of product types and sizes up to 200mm width. Additionally, the XMV-TE provides easy and quick product changeovers.

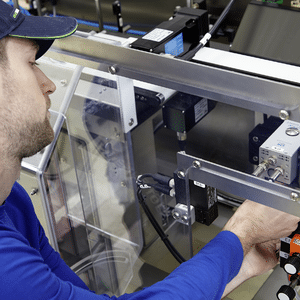

Increased compliance with a complete enclosure with electronic locks preventing access during production providing additional operator safety. The transparent enclosure allows full visibility of the production run.

In-line analysis of the datamatrix code print quality during the production process according to ISO 15415 – supports advanced line performance.

Turnkey solution saves valuable production space and ensures quick and simple integration into new or existing production lines. Inside deflectors and a bottom plate contribute to easy and fast production line clearing.

Use PCE Line Manager (PLM) software for complete line control of production processes for serialization. Choose PCE Site Manager (PSM) for enterprise integration with site-wide IT infrastructure.

Meets current regulatory requirements such as EU delegated act 2011/62 EU and related tamper-evident norm EN 16679. Easily upgrade the software to meet future compliance requirements as needed.

A global network of service experts provides fast remote and on-site support. Our comprehensive service offering allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.