Na parte 2 do série vision blogs, falaremos sobre o Pack-By-Layer.

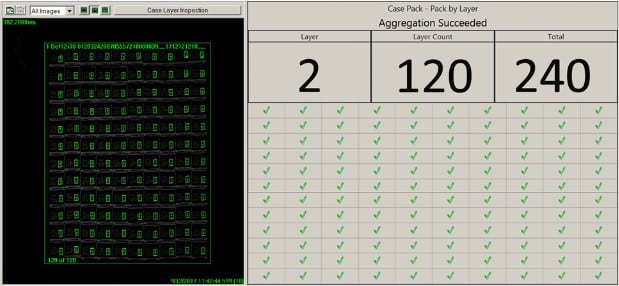

Embalagem por camada é uma solução de agregação em que todos os itens embalados em uma camada de uma embalagem são lidos pelo sistema de visão com uma imagem de alta resolução. Há muitas vantagens nisso em processos manuais, pois evita que os operadores tenham que escanear manualmente cada item antes da embalagem, o que consome muito tempo e é propenso a erros.

Ter uma câmera suspensa que lê enquanto você embala, e você pode olhar para a tela para verificar o processo, parece uma operação muito mais confiável e fácil de usar. Isso também funciona muito bem com processos automatizados, pois diminui os riscos envolvidos, e há um pouco de história nisso.

Antes que a tecnologia da câmera se atualizasse, do ponto de vista da resolução, toda a agregação era feita de uma forma de alimentação: lendo um item de cada vez, ou talvez um grupo de itens que compõem uma linha de uma camada - não uma camada inteira, e por meio da troca de sinais, o serialização O mecanismo pode rastrear esses itens à medida que eles são formados em fileiras e, em seguida, em camadas e, finalmente, colocados ou empurrados para dentro da caixa - o que pressupõe que tudo o que foi lido e aceito na entrada será colocado na caixa. Em geral, isso é bom e funciona bem na maioria das situações... e mesmo que não funcionasse, não havia outras opções porque a leitura de mais itens por vez não era possível devido às limitações de resolução da câmera.

Esse método de alimentação tem alguns riscos, devido aos muitos "e se" que o mundo real pode lançar no processo de empacotamento de caixas:

Essas são apenas algumas das coisas que podem atrapalhar o processo de agregação que depende da leitura na alimentação. Muitos desses riscos poderiam ser evitados se a leitura do que está sendo embalado acontecesse quando a camada estivesse totalmente construída. A parte difícil é o lado da visão - garantir que isso seja possível agora que temos essas câmeras sofisticadas.

A solução de um Visão da Systech A perspectiva do DataPrint passou por iterações de aprimoramentos, cada uma delas tirando lições do que foi feito antes. Ela foi introduzida como um novo recurso em nossa ferramenta de matriz de dados existente para permitir a leitura no modo de grade. Desde o início, a direção era fazer com que os detalhes da grade (número de linhas x colunas) viessem do sistema Systech nível 3 como parte da configuração do produto. À medida que mais projetos foram implantados, os requisitos e desafios para essa inspeção visual tornaram-se muito mais claros, o que levou à criação de uma ferramenta totalmente nova, feita especificamente para a leitura de uma grade de códigos de matriz de dados com recursos que permitem que ela funcione nesse ambiente.

Essa nova ferramenta, feita sob medida para o Pack-By-Layer, foi criada com um tipo diferente de funcionalidade de treinamento que tornou a inspeção de cada camada única no que se refere às especificidades de como a ferramenta encontra e lê os códigos. Em operações de empacotamento manual ou automatizado de caixas de carga superior, espera-se que cada camada esteja a uma distância diferente da câmera, o que significa que cada camada terá códigos de tamanho diferente das outras camadas, e a localização dos códigos na imagem também será diferente à medida que cada nova camada estiver cada vez mais próxima da câmera. O fato de a ferramenta ser construída com essa teoria de operação permite a leitura de códigos menores, uma operação mais rápida, pois a ferramenta sabe melhor onde esperar os códigos em cada camada e taxas de leitura mais altas, pois também sabe o tamanho dos módulos nos códigos de cada camada.

Tudo isso é ótimo, mas não seria possível sem a capacidade de refocalizar automaticamente a lente quando essas novas camadas são introduzidas - portanto, a inovação no lado do hardware também foi necessária para viabilizar as grandes ideias do software de visão. À medida que uma nova camada é colocada, o software envia instruções de distância focal para um servomotor conectado à câmera que ajusta o foco na lente para produzir uma imagem nítida que a ferramenta de visão usa para ler os códigos. É bonito, elegante e funciona bem também, graças principalmente à inovação na visão. Isso não é teórico, há locais que dependem disso em suas operações diárias de alto volume, embalando de algumas a centenas de caixas por camada.

Para saber mais sobre essa solução inovadora, a Systech oferece um serviço abrangente e multifacetado programas de treinamento-adaptado ao seu nível de conhecimento e às suas metas, para garantir que cada cliente seja totalmente treinado em nossas poderosas soluções de visão, serialização, rastreabilidade e autenticação. Veja nossas ofertas de cursos atuais aqui.